Injection Moulding – Precision, Innovation, Excellence

At AC Plastics, we specialise in thermoplastic injection moulding, combining cutting-edge technology, high-quality tooling, and a wide range of thermoplastic polymers to deliver consistently precise mouldings that meet our customers’ exact specifications.

Need a UK injection moulding company to support your next project? Contact us today to discuss your moulding requirements.

Advanced Moulding Technology for Superior Results

We operate 25 state-of-the-art injection moulding machines, with clamping forces ranging from 30T to 650T, sourced from the industry’s most trusted names, including Kraus Maffei, Battenfeld, BOY, and Demag. These machines are equipped with the latest robotic automation and complemented by modern, efficient ancillary equipment, ensuring smooth, high-performance production at every stage.

Round-the-Clock Production, Flexible to Your Needs

With a dedicated team of over 50 skilled professionals, we run production 24 hours a day, 5 days a week, with the flexibility to extend to 24/7 when production demands call for it. Whether it’s a large-scale project or a quick turnaround, we’re ready to meet your needs with precision and speed.

Uncompromising Quality, Every Time

At AC Plastics, we pride ourselves on delivering quality components every time. Our combination of advanced equipment, expert team, and commitment to excellence ensures that your product is produced to the highest standards, consistently

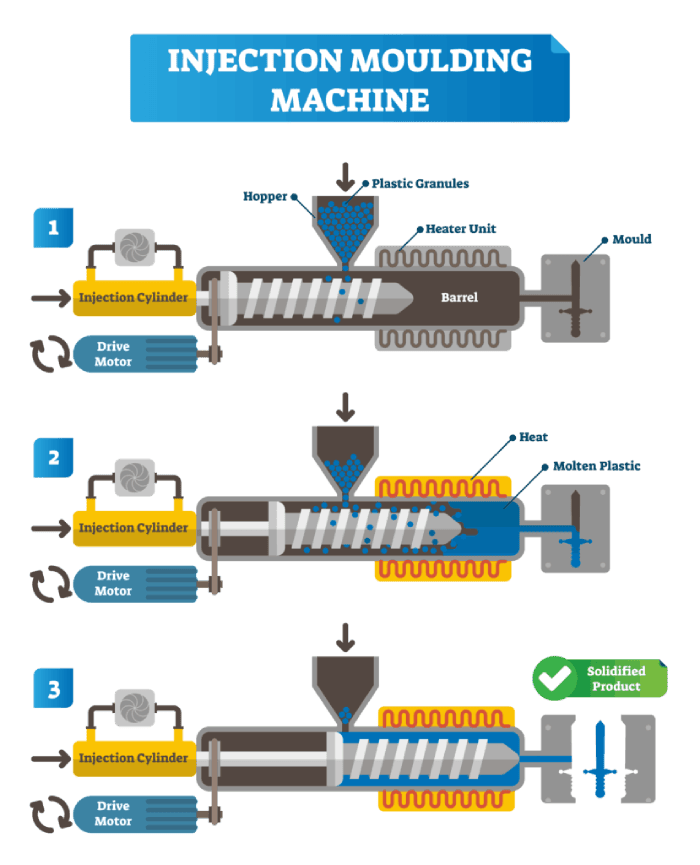

How Does Thermoplastic Injection Moulding Work?

Thermoplastic injection moulding is a highly efficient process where plastic pellets (thermoplastic polymers) are melted into a liquid state. Using advanced moulding machines, this molten plastic is then injected into precision-engineered bespoke tooling to create high-quality, intricate mouldings.

The Key Benefits of Thermoplastic Injection Moulding

Thermoplastic injection moulding offers a host of advantages, making it an ideal manufacturing solution for a wide range of applications and industries. Here’s why it’s a go-to method for so many:

- Cost-Effective – Ideal for large production runs, reducing unit costs significantly.

- Consistency – Ensures each component is identical, delivering reliable results every time.

- Design Flexibility – Accommodates complex designs and intricate details, opening up endless possibilities.

- Low Waste – Maximises material efficiency, making it an eco-friendly option.

Need more information about our injection moulding capabilities? Get in touch — we’re here to answer any questions.