Injection Moulding for the Oil & Gas Industry

Due to the perilous conditions in which activities in the oil and gas sector often take place, mechanical failure can have catastrophic consequences. It is essential for companies within the supply chain of the oil and gas industry to have access to reliable, high-quality products and equipment. AC Plastics’ expertise and meticulous approach to quality ensure that our components are equipped to withstand harsh environments time and time again.

Benefits of Injection Moulding for Oil & Gas

Plastic injection moulding offers significant advantages for the oil and gas industry:

- Material Versatility: A wide variety of materials can be used, making it possible to meet demands for extreme temperatures, high wear, and corrosive chemical conditions.

- Durability: Components are designed to withstand the harshest environments, ensuring long-term reliability and performance.

- Precision and Customisation: Injection moulding allows for the development of highly precise and customised components tailored to specific applications.

- Cost-Effective: High-volume production reduces costs while maintaining consistent quality.

Applications in the Oil & Gas Industry

We provide a range of components specifically designed to meet the rigorous demands of the oil and gas sector, including:

- Seals and Gaskets: Durable and resistant to extreme conditions.

- Valve Components: Precision-engineered parts for reliable performance.

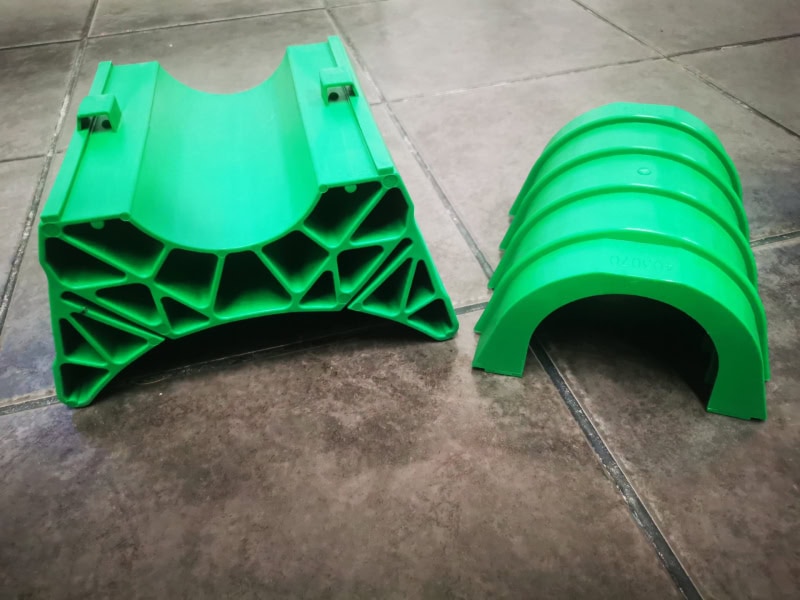

- Pipeline Supports and Spacers: Robust components designed to withstand harsh environments.

- Safety Equipment: High-quality, reliable parts essential for operational safety.

- Custom Solutions: Tailored components to meet specific requirements and operating conditions.

Why Choose AC Plastics for Oil & Gas Injection Moulding?

- Extensive Experience: Decades of expertise in providing injection moulding solutions for the oil and gas industry.

- Advanced Technology: Utilising cutting-edge injection moulding equipment for superior precision and quality.

- Skilled Engineers: A dedicated team focused on delivering high-quality, reliable components.

- Custom Solutions: Tailored designs to meet the unique needs of oil and gas applications.

- Regulatory Compliance: Adherence to all relevant industry standards and regulations.

So, if you have a design or existing product for these industries and typical applications, please contact the team at AC Plastics. We can assist with product design, material choice, along with our tooling and moulding expertise. Partner with AC Plastics for your oil and gas injection moulding needs and benefit from our commitment to quality, innovation, and reliability. Contact us today to discuss your project and discover how our injection moulding expertise can enhance your oil and gas operations.