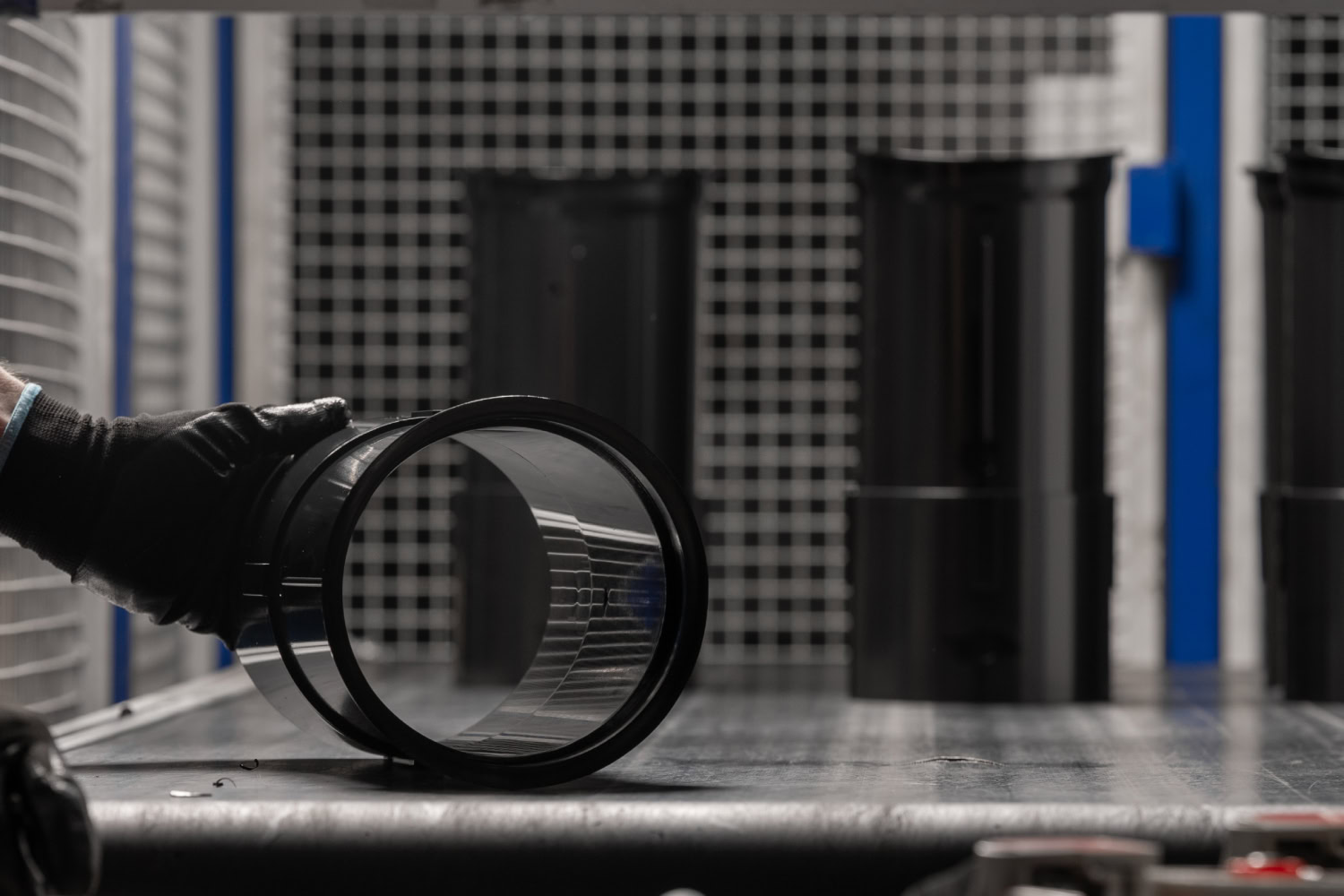

Product Assembly – Complete Support for Your Manufacturing Needs

At AC Plastics, we go beyond manufacturing by offering a full range of post-moulding operations, reinforcing our commitment to being your trusted onestop shop. Our bespoke assembly services are designed to help you reduce unit costs and streamline production timelines.

We can seamlessly assemble mouldings with your provided components, or, if preferred, take on the responsibility of sourcing external parts, delivering a comprehensive supply chain solution

Comprehensive Assembly Services

Our assembly department is fully equipped to handle a variety of processes, ensuring your product is ready for market, on time and to the highest standard. Our capabilities include:

- Complex Sub-Assembly & Full Product Assembly

- Ultrasonic Welding – For strong, precise joins.

- Hot Melt Glue Bonding – Offering secure, durable bonding solutions.

- Inserting – Heat staking or cold press inserts for added functionality.

- Mechanical Fixings – Ensuring strength and reliability.

- Printing – Pad printing or screen printing for branding and details.

- Post-Production Testing – To ensure every component performs to specification.

Streamlined Warehousing & Distribution

We offer extensive warehousing to store your finished items and manage distribution efficiently. Using external carriers or our own transport, we handle UK and international shipments.

By combining assembly, warehousing, and distribution, we cut costs and free up valuable space, streamlining your operations.