Automotive Injection Moulding Excellence

Since the introduction of mass-produced polymers in the 70’s and 80’s, the automotive industry has been at the forefront of thermoplastic moulding. Plastic injection moulding in the automotive sector offers significant advantages, including reduced vehicle weight, increased fuel efficiency, and improved responsiveness. By replacing heavier steel and aluminium components with lightweight plastic parts, manufacturers can reduce emissions and enhance vehicle performance.

Benefits of Automotive Injection Moulding

- Weight Reduction: Lighter parts improve fuel efficiency and vehicle responsiveness.

- Cost Efficiency: Lower production costs and shorter lead times.

- High Repeatability: Consistent quality with mass production.

- Variety: A wide range of colours and finishes available.

- Design Flexibility: Complex shapes and detailed designs can be easily achieved.

AC Plastics’ Automotive Experience

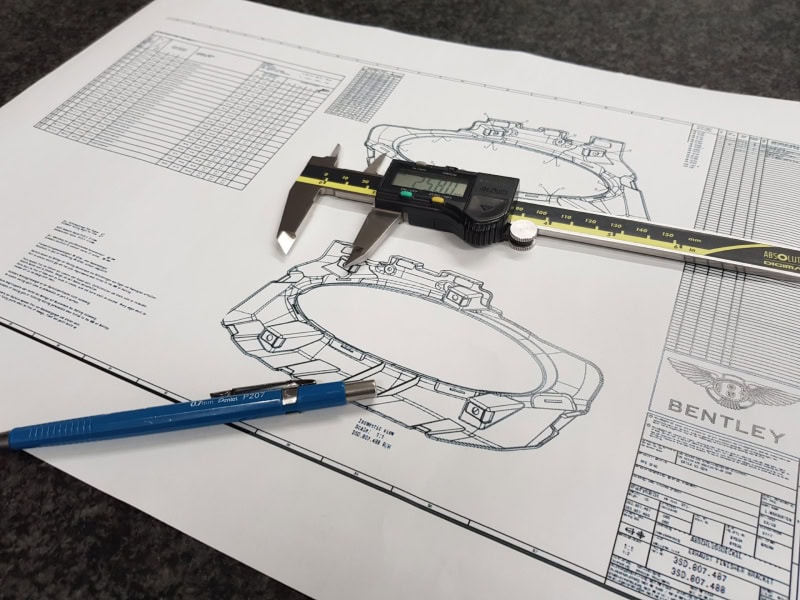

AC Plastics has been a trusted provider of automotive injection moulding products and services since 1997. We collaborate with Tier 1 suppliers to some of the world’s leading automotive OEMs, including Aston Martin, Bentley Motors, McLaren, Honda, and Jaguar Land Rover. Our expertise and systems are tailored to meet the rigorous demands and standards of the automotive industry.

Our Automotive Injection Moulding Capabilities

- Heat Resistant Exhaust Surrounds

- Engine and Lighting Clips and Housing Covers

- Wiring Harnesses and Connectors

- Exterior Badging Parts

- Console and Dashboard Covers and Brackets

- Cup Holders and Internal Components

- Knobs for Shifter Levers and Control Levers

- Buttons and Bezel Panels

- Complete Door Handles

Why Choose AC Plastics for Automotive Injection Moulding?

- Advanced Technology: Utilising the latest injection moulding technology to deliver superior products.

- Quality Assurance: ISO 9001 certification ensuring high-quality components throughout.

- Experienced Team: Skilled engineers dedicated to maintaining the highest standards.

- Customer Focus: Tailored solutions to meet specific client needs and industry standards.

- Innovative Solutions: Continuous investment in technology and processes to stay ahead in the industry.

Partner with AC Plastics for your automotive injection moulding needs and benefit from our extensive experience, quality assurance, and commitment to innovation. Contact us today to discuss your project and discover how our injection moulding expertise can enhance your automotive products.