Injection Mould Toolmaking

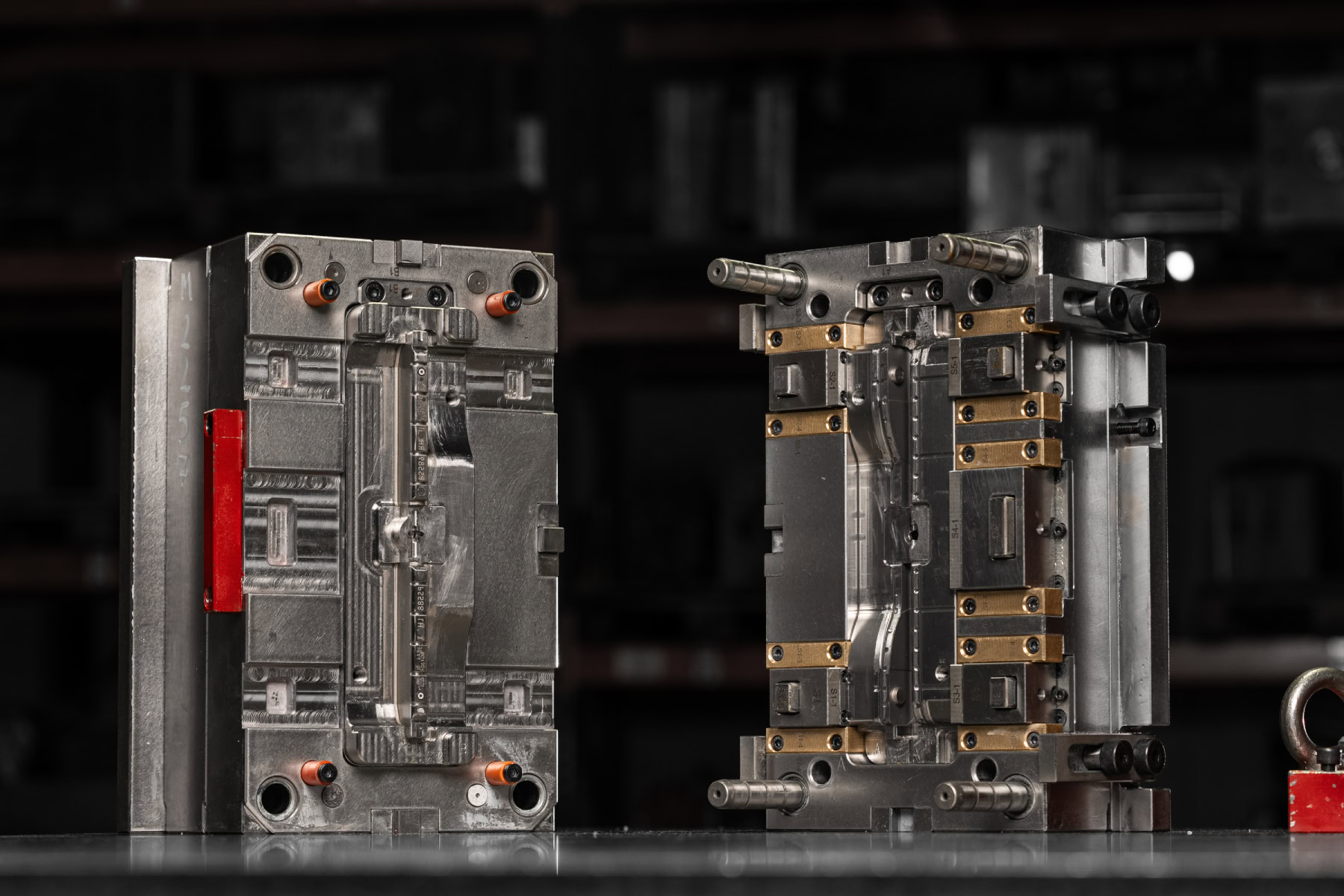

The mould tool is possibly the most important part of the injection moulding process. Throughout the life of the tool, it will be required to produce high quality components hundreds, thousands and even millions of times. It must be right every time.

We have extensive knowledge and many years’ experience when it comes to injection mould tooling. Whether you are looking for a competent moulder to take your existing

tooling or need guidance with a new tooling project then AC Plastics is here to help.

If you require a single tool or a multi tool ‘suite’ then we can assist you every step of the way. From relatively low volume single impression tools to high volume, multicavity tools. AC Plastics can specify and have manufactured tooling of the highest quality.

Ready to bring your injection mould tool to life? Reach out via our Contact Us page to get started.

Choosing the right tool

Production volume, dimensional tolerances and cost all play a major part when deciding the makeup of an injection mould tool. High volume production tooling can be made from high quality, fully-hardened steel. They are extremely durable and long lasting, but more expensive to construct.

Less abrasive materials might only require softer steels. Prototype or low volume components could be made from aluminium to keep costs low.

Our engineers can advise you of the right mould for your project and ensure you get the maximum life and quality for your product.

Our knowledge is our key strength

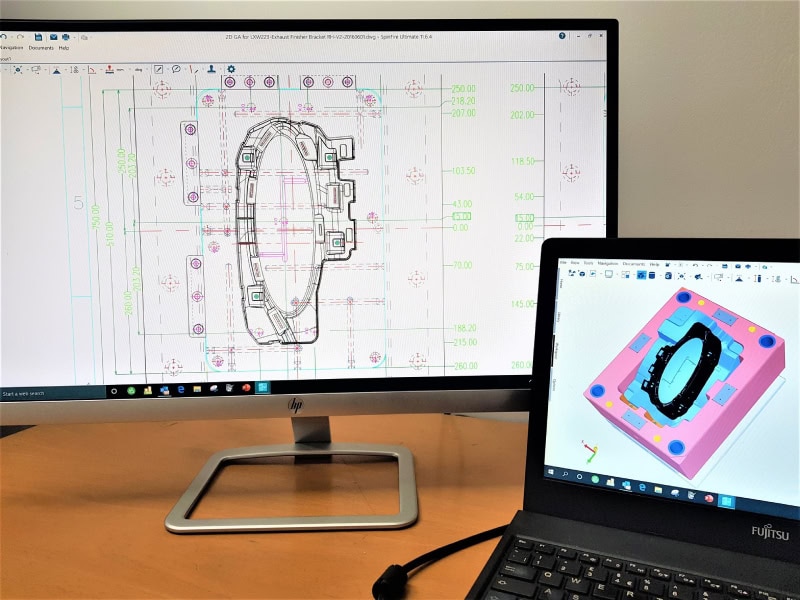

Design & Development

When developing a new injection moulding tool, initial design and review is the most critical process. You can iron out all the issues, specifications and tolerances to produce a high quality, long lasting and cost-effective tool.

Detailed analysis

Your business has access to the very latest machinery and experienced design engineers. This combination means your designs can be taken from a multiple array of file types and rapidly turned into

prototypes or go directly into production.

Specialist mould flow analysis will assess any potential issues. This process simulates the flow of liquid material in the mould creating colour maps of the different properties in the design.

Everything from heating/cooling, injection pressure, air traps, stress, fibre orientation and much more is tested saving a huge deal of effort, time and cost further down the process.

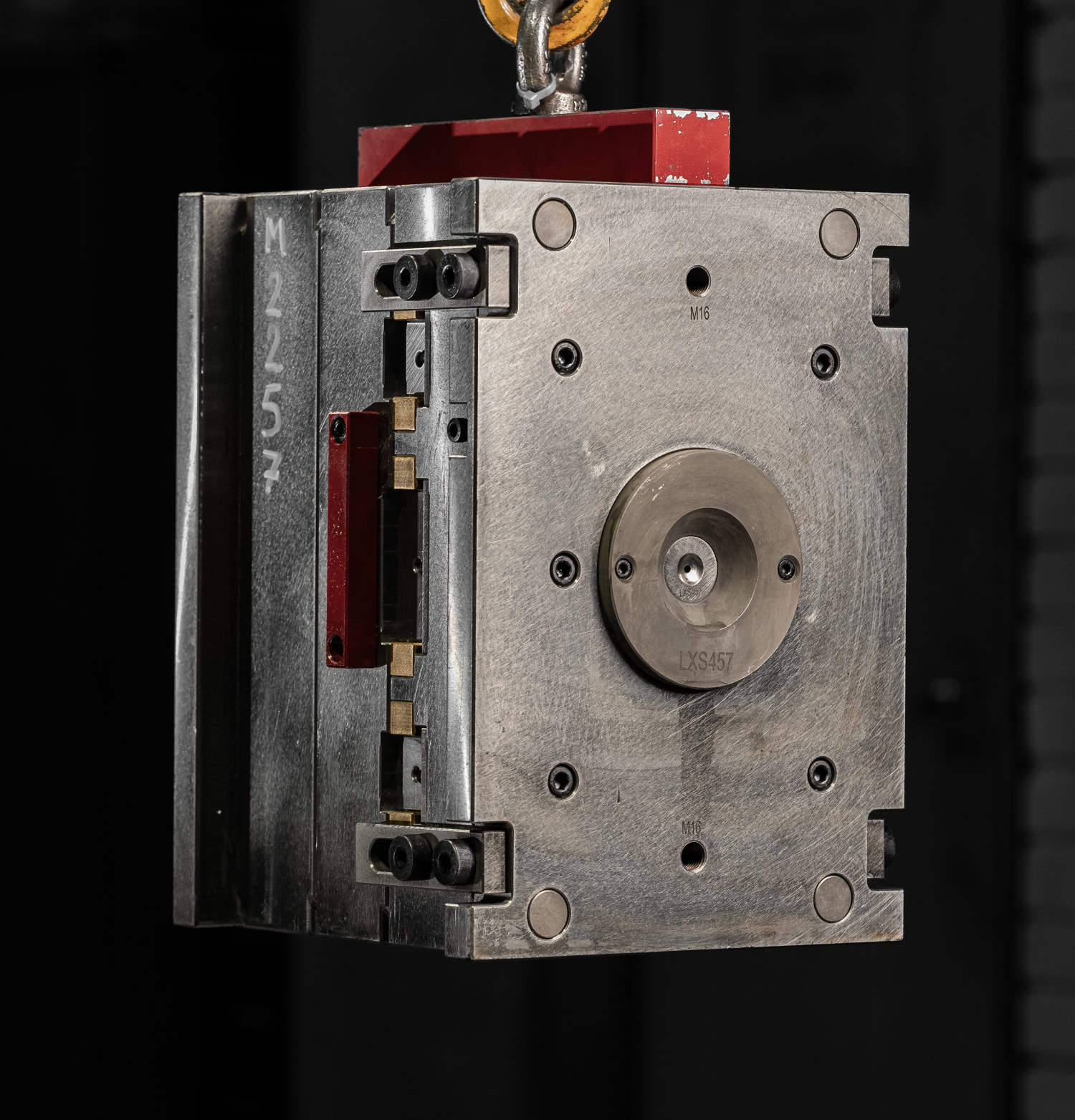

Transferring an existing mould

If you have existing injection mould tooling based in the UK or internationally and would like to talk to us about transferring it to us, we will assist with the transportation of the moulds and with our in-house toolroom we can inspect and prepare all incoming tooling to ensure it is production ready on one of our 25 injection moulding machines.

Have a mould tool you’d like to transfer to us? Contact us today — we’ll handle everything from transportation to production readiness.

Turning Ideas into Precision Components

Leveraging our years of expertise, we analyse your design with meticulous attention to detail, specifying the right materials and ensuring your product is not only fit for purpose but optimised for

performance. Through a comprehensive review process, we guarantee your tooling is precisely what you need, every time:

- Mould Flow Analysis

- DFMEA (Design Failure Mode and Effect Analysis)

- 3D GA Review

This thorough review ensures high-quality tooling, ready to produce components that meet the highest standards.

Thermoplastic materials and colours

As well as having the right mould tooling, it is essential that the plastic material is suited to the application. The performance, longevity and overall appearance of your products will depend on the plastic materials and colours you choose.

There are 85,000 commercial options when choosing a thermoplastic material, which is why it is essential to talk to an engineering expert.

Choosing the right material will depend on many things. What is the primary function of the component? What environment will the component be operating in? What other materials will it be used in conjunction with? Everything from medical instruments, electrical components and automotive components need assessing to ensure the right thermoplastic material is selected for the job. AC Plastics has the expertise and knowledge that will make sure you make the right decision for your product.