Mould Plastic to any Pantone or RAL

Moulding with plastics allows you to colour the plastic products you are making to any Pantone® or RAL. You may need to colour your plastic product for safety or functional reasons or simply because it looks better. The choice of colours available is more or less endless, however it is the point at which the colours are added that is different.

Option 1 – Compounding

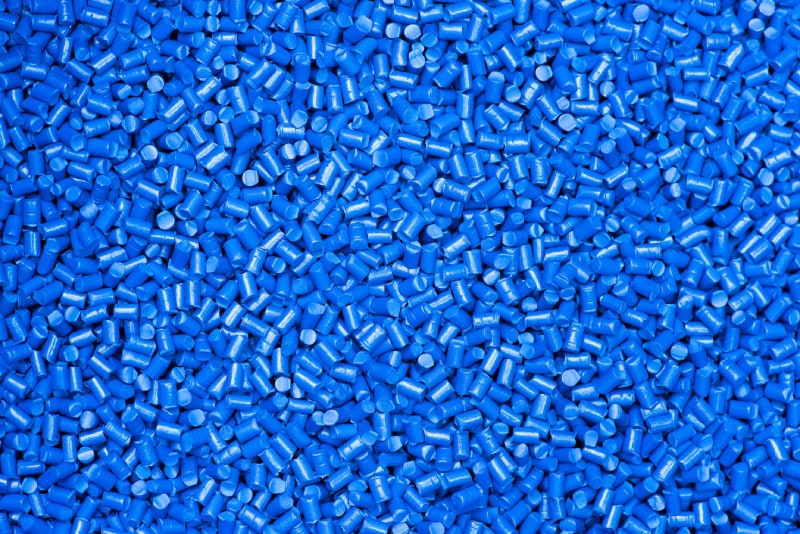

Compounding is when the base material is coloured in a controlled process before moulding begins

Option 2 – Masterbatch

Masterbatch is when concentrated coloured pellets or liquid are mixed with the base material as it melts during the injection moulding process.

Compounding pros and cons

If consistency is critical then compounding delivers the most even distribution of colour in the production process. The colour is mixed with the base material during manufacture which delivers the plastic granules ready coloured. No pre-mixing or measuring material is required and you get a consistent, repeatable colour.

This process is most suited to larger volumes as an additional process has been introduced into production. Also it can add to the lead time for the same reason. But as volumes increase it becomes more economical.

Masterbatch pros and cons

Masterbatch is a solid concentrate of colour supplied mostly in a solid granular form or but it can also be a liquid. Colour is applied when the granules melt and mix with the plastic as it moves through the barrel of the injection moulding machine before the cavity is filled.

As this is being adding during the production process lead times are not affected and costs are reduced. However, the ratio of colour pigment to polymer can vary slightly during the process and deliver inconsistencies in the final product.

Colours can be universal or polymer-specific so as not to adversely affect the physical properties of the material. They can therefore be adapted for use with commodity and most engineering plastics, as well as transparent polymers.

Multiple colours

Masterbatches can use combinations of colours, metallic and sparkle effects are all possible.

The end use of the product being manufactured, polymer type and production volumes will determine which method is best for adding colour. In terms of choice, that’s entirely down to the functionality of the item or your preference