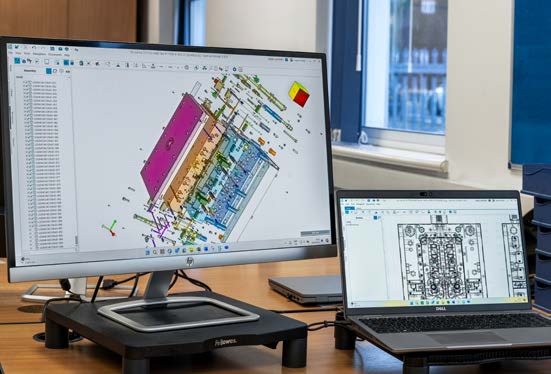

Concept & CAD Development

We help our customers by taking their concepts and turning them into real, manufacturable products. Through close collaboration, we develop 3D CAD models that bring ideas to life, optimising design and ensuring functionality. These detailed models allow us to identify potential issues early, making design revisions more efficient before production begins.

By leveraging advanced CAD software, we can experiment with design variations, materials, and techniques to ensure the final product meets both aesthetic and practical requirements. This approach reduces time-to-market, minimises costly changes, and results in cost-effective, durable, and functional products. With our expertise in both design and manufacturing, we transform customer concepts into high-quality, productionready solutions.

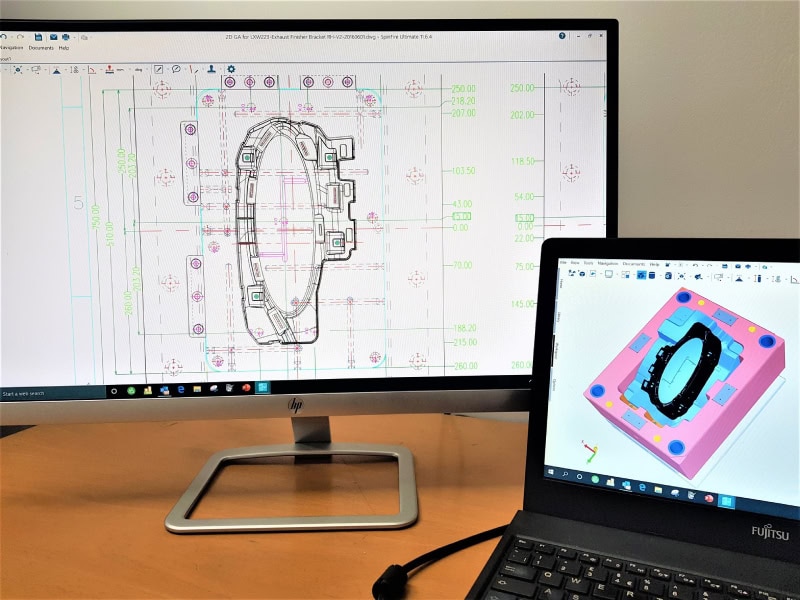

Injection mould tooling

When developing a new injection moulding tool, initial design and review is the most critical process. You can iron out all the issues, specifications and tolerances to produce a high quality, long lasting and cost-effective tool.

We have a specialist in house design team comprising of technicians and toolmakers that can advise and develop designs.

Detailed analysis

Your business has access to the very latest machinery and experienced design engineers. This combination means your designs can be taken from a multiple array of file types and rapidly turned into prototypes or go directly into production.

Specialist mould flow analysis will assess any potential issues. This process simulates the flow of liquid material in the mould creating colour maps of the different properties in the design.

Everything from heating/cooling, injection pressure, air traps, stress, fibre orientation and much more is tested saving a huge deal of effort, time and cost further down the process.

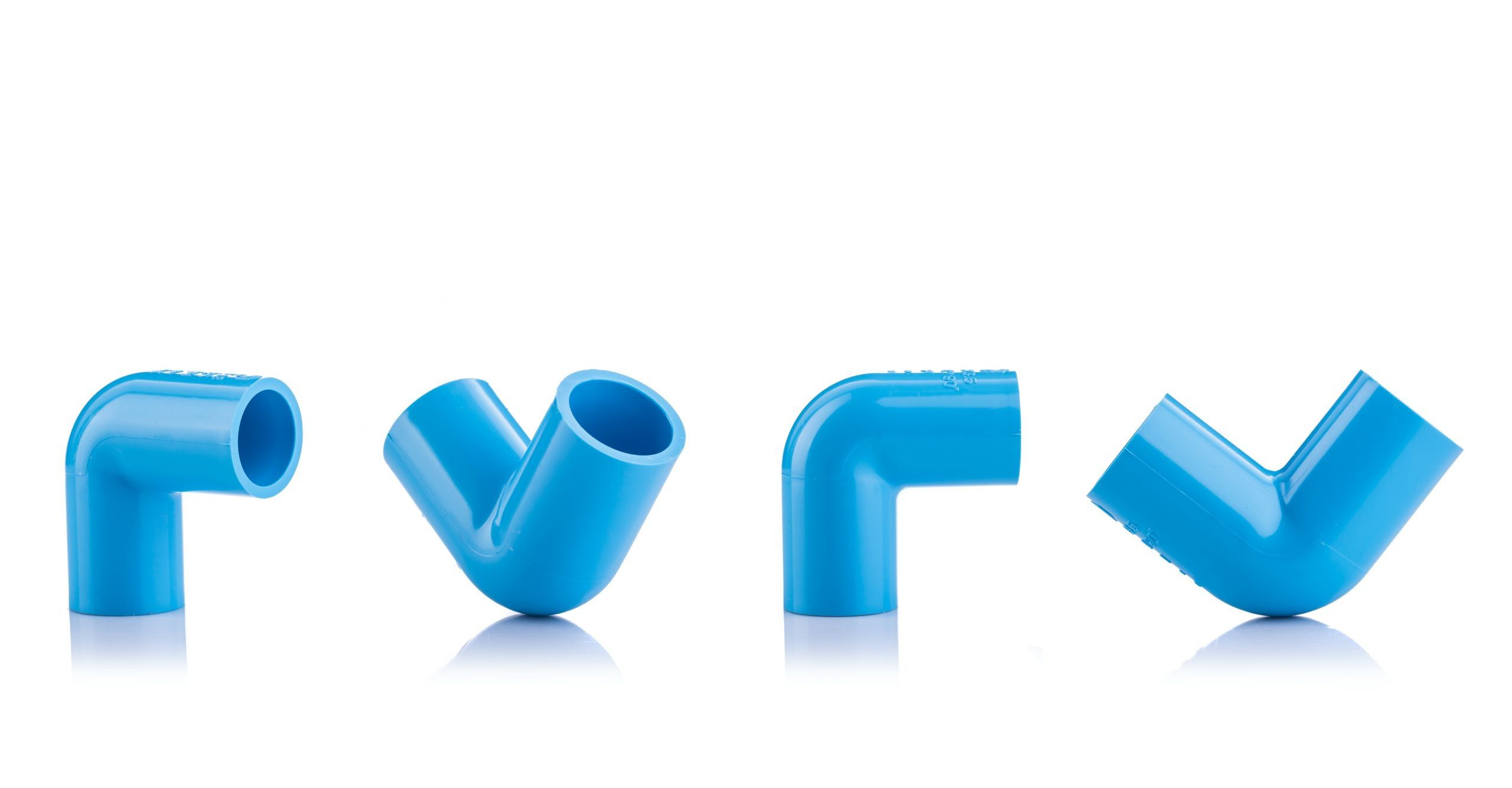

3D Prototyping – Bringing Your Designs to Life

While 2D and 3D drawings are often sufficient for most products, there are instances when you need a 100% accurate, full-size representation of your final design. This is especially critical for proof-of-concept testing, product performance evaluation, or safety assessments.

At AC Plastics, we offer 3D printed prototypes that allow you to physically evaluate your component before moving forward with tooling manufacture. This ensures your product is fully tested and refined before mass production.