What injection mould tool do I need?

To get the right injection mould tool there is a specific process and a set of information you need to know to make sure you end up with the right tool. Injection mould tools can be expensive so getting it right is important. Of course, we will help you every step of the way but here is some useful information.

Do you know what you are moulding?

It sounds obvious but it helps if we know what you are moulding and what materials are being used, not everybody does. Different materials have different flow rates and more abrasive materials will cause erosion to the moulding tool. If cooling is a bigger consideration, beryllium copper inserts have excellent wear properties along with great thermal conductivity.

For lower volume production aluminium might be more suited, but you don’t need to know this before picking up the phone to us. We can guide and advise you based on your objectives, so you choose the right tool.

What machine will you be using?

Tool size and design will determine the size of injection moulding machine that will be needed to mould your component.

We have 25 injection moulding machines in our 25,000sq feet capacity premises. We have Battenfeld, Borche, Boy, Sandretto and Kraus Maffei machines with clamping force ranging from 30 to 650 tonne. Most are equipped with the latest robotics and ancillary equipment.

When do you expect to go into production?

If you are transferring existing tooling to AC Plastics then we can have your mould prepped and ready to run within a couple of days.

For new tooling projects then typically it is 8 weeks from design being finalised to production of T1 samples.

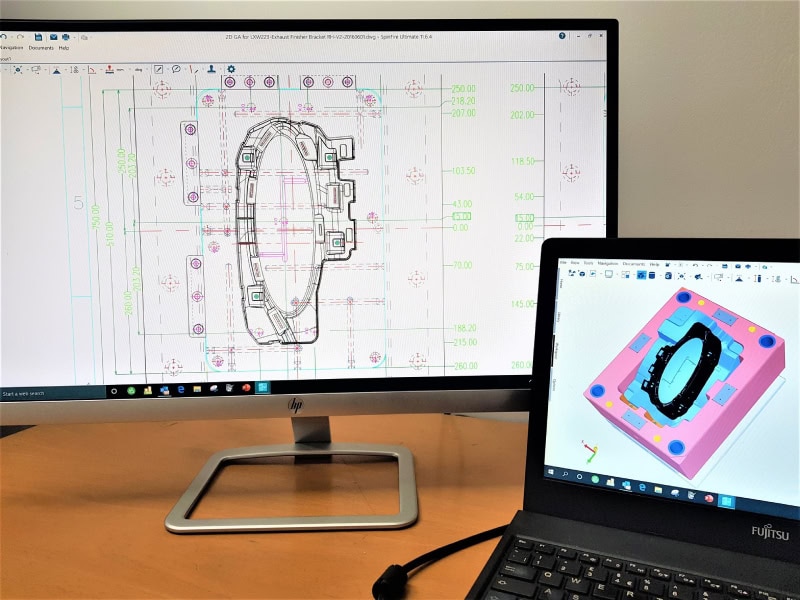

Spend your time getting the design right.

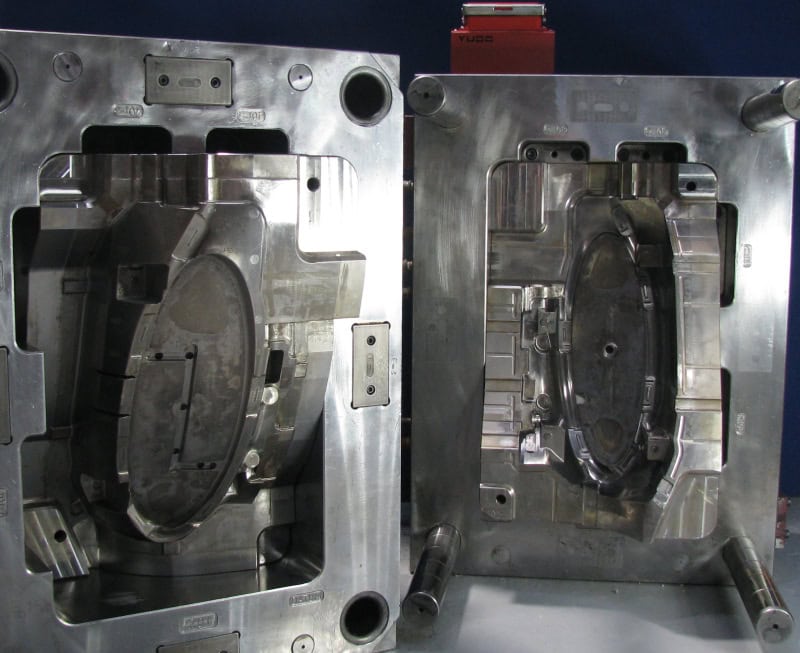

It is essential that all aspects of product design have been reviewed and signed off on before tooling production begins. Any alterations and modifications that need to be carried out once the tool has been made can be time consuming and costly. AC Plastics will work with the customer at every stage of the design to help make sure the component is ready to be tooled.

Once it is time for injection mould tools to be produced, AC Plastics will again assist and oversee the tooling to help reduce time and money spent on modifications and alterations.