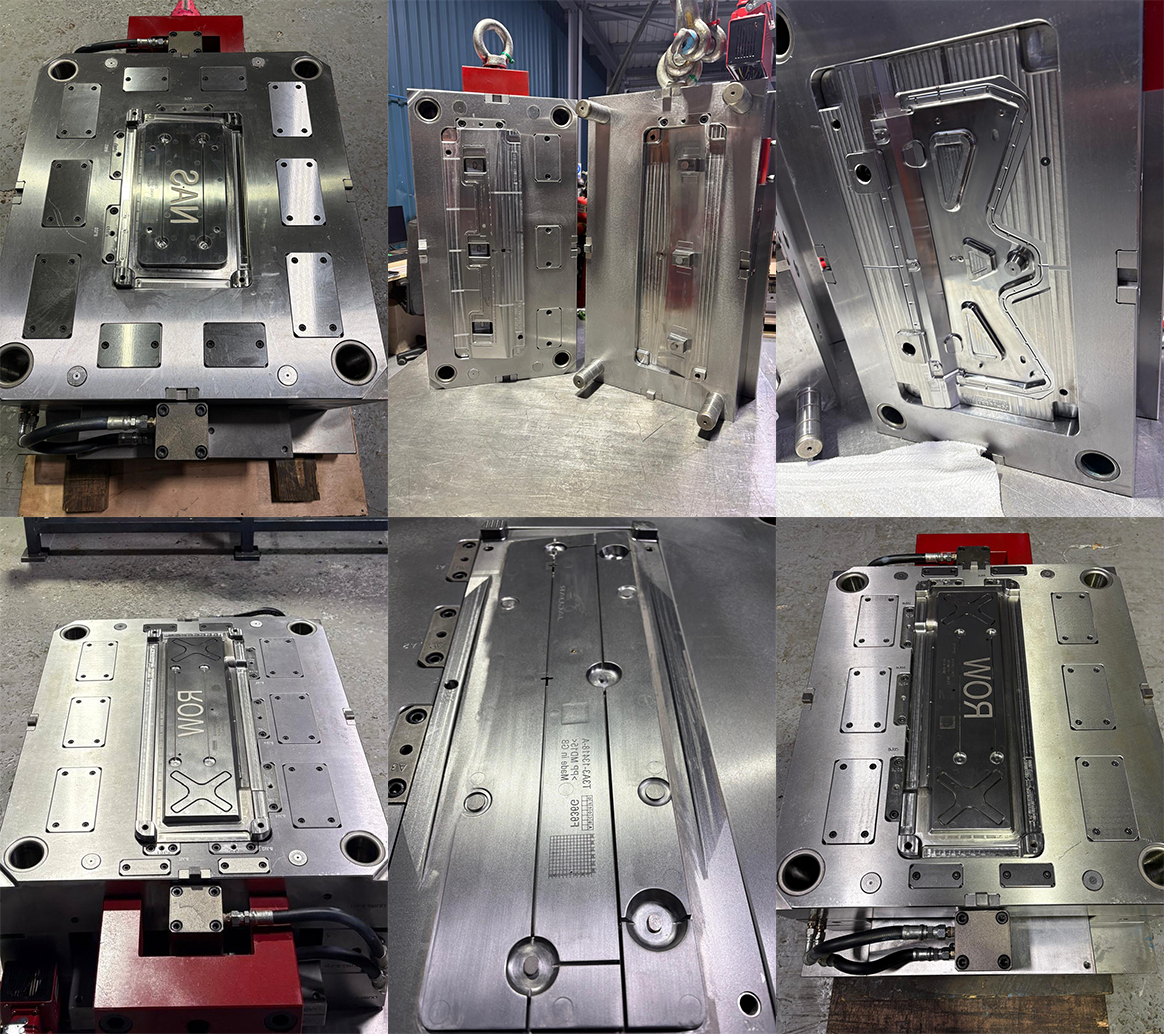

We have taken delivery of 18 new injection mould tools for a major automotive project, marking a key milestone ahead of our production launch in May/June 2026.

The shipment of tools was delivered in November 2025, with tooling costs in the region of £700,000. Following receipt, we completed unpacking and preparation before progressing each tool through our inspection, validation and trial process. All 18 tools were trialled successfully before Christmas 2025, confirming readiness for the next stage of the programme.

Before trials, we run a defined inspection and validation routine to confirm dimensional compliance against customer requirements. This includes scanning the tools and measuring the injection moulding machine to ensure adherence to the CAD model. In addition, we scan all components using our FARO arm measurement device to verify dimensional requirements for the customer prior to trialling.

Martin Gough, Sales Director at AC Plastics, said:

“With an automotive programme of this size, the focus is on delivering consistency from the outset. Completing successful trials on all 18 tools before Christmas keeps the programme on track and supports a smooth run-in to the May/June production start.”

The programme is a strong indicator of continued OEM and Tier 1 investment in new vehicle production, and a positive sign for us and the wider UK manufacturing supply chain as the next wave of automotive launches moves towards production.

Supporting complex automotive moulding programmes

As an established UK injection moulding specialist with more than 60 years of experience in moulding commodity and engineering thermoplastics, supporting customers with precision moulding, custom moulding and assembly. We operate 24/5 across two facilities, with 25 injection moulding machines and 14,000 sq ft of production space.

In the automotive sector, we have supplied injection moulded products and services since 1997 and work with Tier 1 suppliers supporting leading OEMs, including Aston Martin, Bentley Motors, McLaren, Honda and Jaguar Land Rover.

Alongside moulding, we provide end-to-end support spanning design, prototyping, tooling, project management and distribution, helping customers move from early-stage development through to production supply.